Automotive

Register today for Great Designs in Steel!

May 20, 2026

Vibe Credit Union Showplace, Novi, Michigan

(Formerly Suburban Collection Showplace)

View past GDIS presentations and webinars

Click here to sign-up to receive the latest information about Great Designs in Steel including webinars, our 2026 symposium notifications and agenda updates.

GDIS Technical Webinar: Considerations for Design and Stamping of Generation 3 Steel Grades

GDIS Technical Webinar:

Effect of Substrate Composition on Liquid Metal Embrittlement Susceptibility in 3rd Gen AHSS

GDIS Technical Webinar:

Leveraging A.I. for Optimized Vehicle Structural Design with AHSS

GDIS Technical Webinar: Deformation Behaviour of AHSS During V-die Bending

GDIS Technical Webinar: Towards Next Generation CAE & Automotive Steel Developments Driven by Big DATA & A.I

Watch the GDIS™ Technical Webinar: “Comparison of 1500 MPa Ultra High-Strength Steels for Auto Applications”

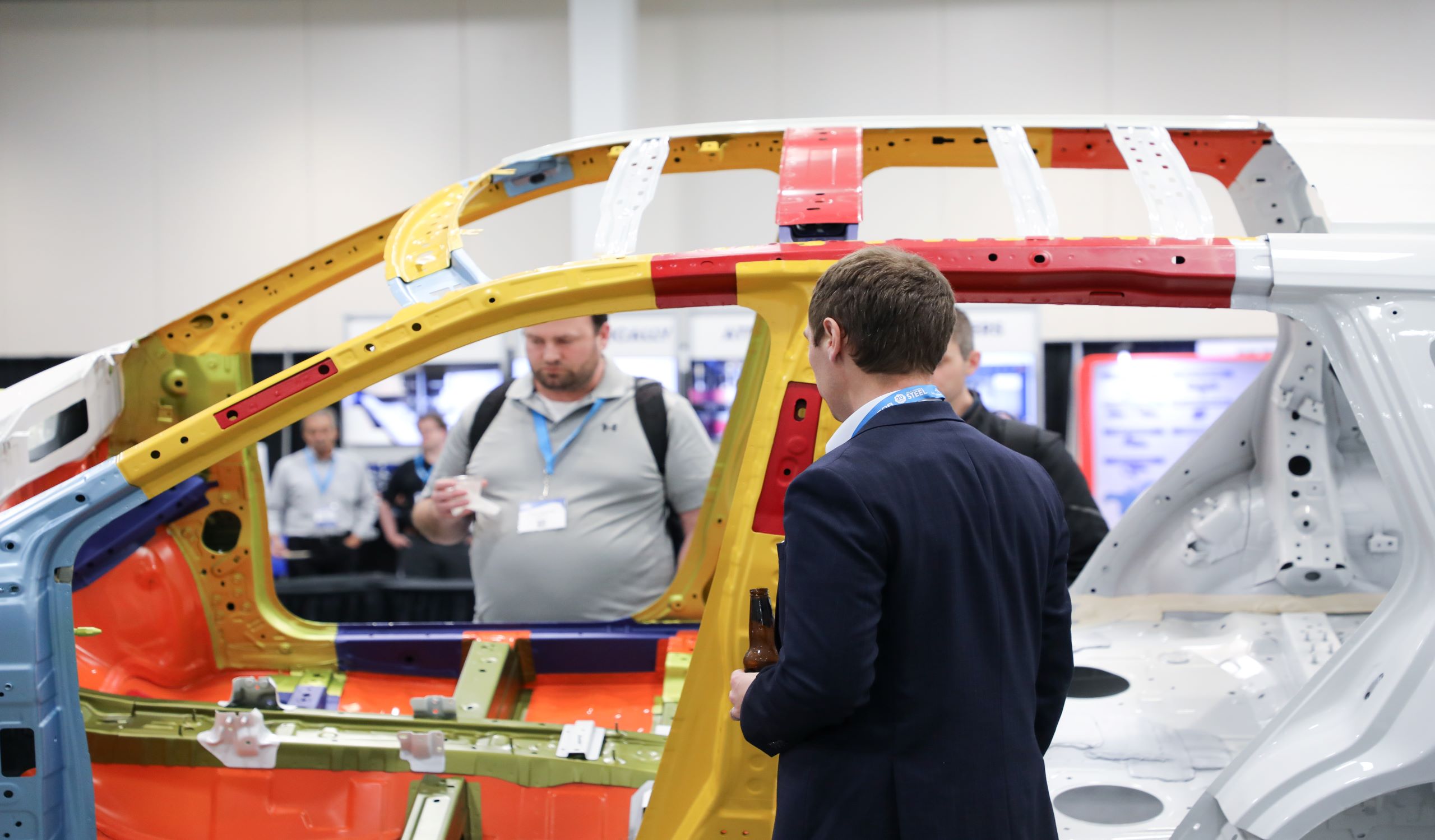

VW ID.Buzz Body-In-White Construction Presentation at Great Designs in Steel™ 2025

General Motors’ D-Segment Crossover Architecture Presentation at Great Designs in Steel™ 2025

Rivian R1 Body Structure Evolution and Repairability Presentation at Great Designs in Steel™ 2025

Watch the Great Designs in Steel™ Technical Webinar: “Press-Hardened Steel in Automotive Applications”

Watch Hesham Ezzat, Ph.D., American Iron and Steel Institute (AISI), explain the Steel Intensive Battery Enclosure Structure (SIBES) project.

A novel approach for precise calibration of force-based RSW failure criteria implemented in LS-DYNA by Mohammad Shojaee, Ph.D., Postdoctoral Fellow at University of Waterloo. View PDF

Watch the Great Designs in Steel™ 2024 Featured OEM Vehicle Presentation by Dr. Hoda Eiliat of General Motors.

Watch the GDIS™ Technical Webinar: “Development of C-STAR™ and CCBE, the Cleveland-Cliffs Battery Enclosure.” View PDF

Watch the Great Designs in Steel™ 2024 Keynote Address by Brad Davey, Executive Vice President of Corporate Business Optimization at ArcelorMittal. View PDF

Steel Offers Durable, Cost-Effective Solutions for Automotive Vehicles

Steel currently makes up about 54 percent of the average vehicle. Americans depend on automobiles to keep families safe. In addition to its strength, durability and dependability, steel is also the key to recycling a car at the end of its long life — as steel is continuously recyclable.

The American steel industry continues to invest in advanced materials and manufacturing technologies that have led to the introduction of a wide variety of new automotive steels. These advanced high-strength steels (AHSS) are strong, lighter, and produced with light life cycle impact, helping automakers decrease a vehicle’s life-long carbon footprint. This helps auto manufacturers to reduce the mass of vehicles while maintaining safety standards — thereby increasing fuel economy and reducing tailpipe emissions. The use of current grades of AHSS can reduce a vehicle’s structural weight by as much as 25 percent and can cut total life cycle CO2 emissions by up to 15 percent more than any other automotive material.

With more than 200 steel grades available, today’s products are six times stronger than those of a decade ago. The steel industry continues to innovate by introducing new grades and manufacturing processes in support of future mobility, which promises to revolutionize the transportation industry through the proliferation of electrified, connected, and shared autonomous vehicles.

As electric vehicles become more commonplace and battery efficiencies improve, use of advanced grades of steel enable reduced weight resulting in a greater range from a single electrical charge.

The American steel industry, working with the automotive industry, continues to revolutionize the safety and durability of cars, while reducing environmental impacts. For more information, enter here.

Read our report: Consequential Life Cycle Greenhouse Gas Study of Automotive Lightweighting with Advanced High Strength Steel (AHSS) and Aluminum.

-

Great Designs in Steel™ Technical Webinar Featured in MetalForming Magazine

July 8, 2025 -

AISI Announces Recipients of 2025 Market Development Industry Leadership Awards

June 3, 2025 -

Auto/Steel Partnership, General Motors and University of Waterloo Receive Award at Annual Great Designs in Steel Symposium

May 21, 2025 -

AISI’s Great Designs in Steel Highlighted in The Fabricator Magazine

April 17, 2025 -

AISI’s Great Designs in Steel Highlighted in MetalForming Magazine

March 31, 2025 -

AISI’s Great Designs in Steel Mentioned in Automotive Engineering

July 26, 2024 -

Great Designs in Steel Featured in Automotive Engineering Article

June 13, 2024 -

General Motors, Magna and Shape Corp. Receive Award at Annual Great Designs in Steel™ Symposium

May 22, 2024

![[AISI LOGO]](https://www.steel.org/wp-content/themes/steel-org/assets/images/steel-logo.png) American

Iron and Steel

Institute

American

Iron and Steel

Institute